OEM Painted Aluminium Coil Supplier: How It Works and Why It Matters

An OEM painted aluminium coil supplier plays a critical role in the supply chain of many industries, including construction, automotive, home appliances, and electronics. These suppliers provide high-quality painted aluminium coils that serve as essential raw materials in the manufacturing of laminates, wall cladding systems, roofing materials, and other end products.

In this article, we will explore how an OEM painted aluminium coil supplier operates, what components are involved in the production process, and why choosing the right supplier matters for your business.

How an OEM Painted Aluminium Coil Supplier Works An OEM painted aluminium coil supplier produces high-quality painted coils that are used in various industries such as construction, automotive, and electronics. These coils are used as raw materials in the production of many products such as laminates, cladding systems, and roofing materials. In this article, we will delve into how an OEM painted aluminium coil supplier works and its key components. The key components of an OEM painted aluminium coil supplier are the raw materials, the painting line, and the quality control system. The first step in the process is the raw material selection. The supplier carefully selects the aluminium material depending on its properties, such as its strength, durability, and corrosion resistance. The painting line is the core component of the manufacturing process. The painting line is composed of several sections, including the pre-treatment section, the coating application section, and the curing section. In the pre-treatment section, the aluminium coils are cleaned and prepared for coating. The coated aluminium coil is then passed through a series of rollers, which evenly distribute the coating material. This process is called the coating application section. After the coating is applied, the coils are then passed through an oven where the coating is cured, creating a smooth, long-lasting finish that can last for many years. In modern manufacturing, advanced technology is used in every aspect of the production process. The same is true for an OEM painted aluminium coil supplier. In many cases, the painting lines are computer-controlled, allowing for precise control over the coating thickness and quality. This technology also enables the efficient production of large volumes of painted aluminium coils, which is crucial in meeting the demands of industries that require high volumes of raw materials. The importance of advanced technology cannot be overstated in modern manufacturing. Suppliers that use outdated techniques to produce painted aluminium coils often produce substandard products that can be detrimental to the final product, affecting the quality of the end product and longevity. Therefore, it is necessary for the painting line to operate using the latest technology to ensure that the end product is of the highest quality and durability. In conclusion, an OEM painted aluminium coil supplier works by carefully selecting raw materials, passing them through a painting line consisting of several sections, and using advanced technology to ensure precise control over the coating thickness and quality. This ensures the production of high-quality painted aluminium coils that can be used in various industries. It is important to contact a trustworthy supplier to ensure that you receive the best quality product for your manufacturing needs. If you are looking for reliable painted aluminium coil suppliers, do not hesitate to contact us. We are committed to producing high-quality painted aluminium coils that meet the needs of our customers.

What Does an OEM Painted Aluminium Coil Supplier Do?

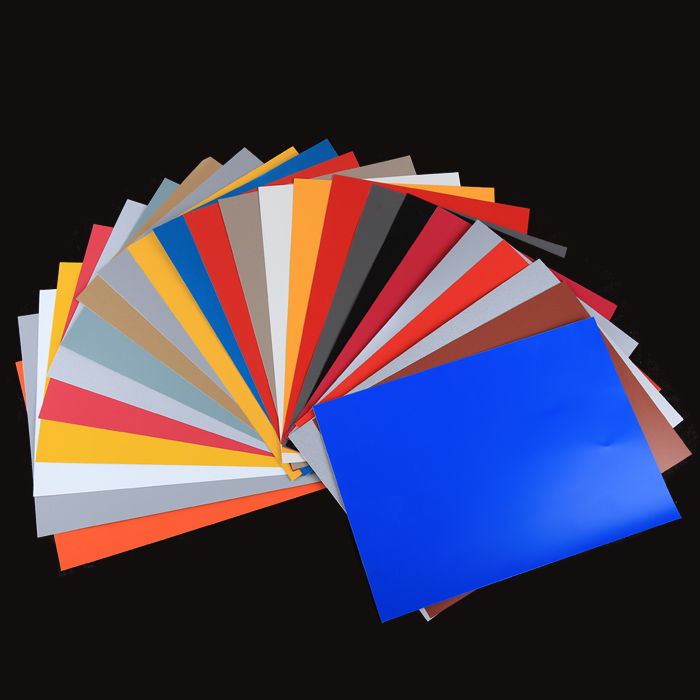

An OEM painted aluminium coil supplier specializes in producing and delivering aluminium coils that are pre-painted according to customer specifications. These coils are tailored to meet specific requirements such as color, coating thickness, durability, and surface finish. They are widely used in sectors where aesthetics and performance are both critical.

If you're sourcing reliable aluminium coil products, feel free to explore our full range of painted aluminium coil products.

Key Components of the OEM Painted Aluminium Coil Manufacturing Process

1. Raw Material Selection

The process begins with selecting premium-grade aluminium. A professional OEM painted aluminium coil supplier prioritizes material properties such as tensile strength, corrosion resistance, and flexibility. The right raw material ensures durability and optimal performance in the final application.

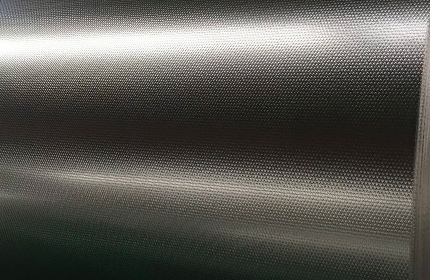

2. Painting Line Technology

The heart of the operation is the painting line, which includes:

-

Pre-treatment Section: Cleans and prepares the aluminium surface for coating.

-

Coating Application Section: Applies the desired paint using rollers and precision equipment.

-

Curing Section: Heats the coated coil in ovens to ensure proper adhesion and finish.

Modern OEM painted aluminium coil suppliers employ automated, computer-controlled painting lines. This ensures uniform coating thickness, reduced waste, and superior product consistency.

3. Quality Control Systems

Throughout production, stringent quality checks are conducted. These include color matching, adhesion tests, gloss level measurement, and durability simulations. Only coils that meet strict criteria proceed to packaging and shipment.

Why Technology Matters in Painted Aluminium Coil Production

An experienced OEM painted aluminium coil supplier uses state-of-the-art equipment to deliver precision-engineered coils. Outdated equipment can lead to poor coating quality, color inconsistencies, and reduced coil lifespan. In contrast, a modern supplier guarantees:

-

Consistent coating thickness

-

Enhanced corrosion resistance

-

Custom color matching

-

Increased production efficiency

Want to discover more advanced aluminium coil options? Browse our product catalog here.

Choosing the Right OEM Painted Aluminium Coil Supplier

Partnering with a trustworthy OEM painted aluminium coil supplier ensures your products meet industry standards and customer expectations. When selecting a supplier, consider the following:

-

Years of experience in OEM coil production

-

Investment in technology and automation

-

Track record of delivering consistent quality

-

Range of customization options available

We pride ourselves on being a leading OEM painted aluminium coil supplier with a commitment to quality, service, and innovation.

Conclusion

An OEM painted aluminium coil supplier is more than just a manufacturer—they are a critical partner in your product development process. From raw material selection to precision coating and final inspection, every step is designed to ensure the highest quality painted aluminium coils.

If you're in need of a reliable OEM painted aluminium coil supplier, contact us today to find out how we can support your business with custom coil solutions.